NEXT LEVEL

EFFICIENCY

Die TMG Consultants ist das Beratungsunternehmen, wenn es darum geht, Ihr Unternehmen noch effizienter zu machen.

Unser Ansatz ist es, Ihre Stärken, Ihre Prozesse und Ihr Know-how auf das nächste Level der Effizienz zu heben. Wir sind davon überzeugt, dass wir gemeinsam mit Ihnen Ihr Unternehmen ganzheitlich noch produktiver und dadurch erfolgreicher machen.

Individuelle Beratung

TMG Consultants: die ganzheitliche Beratung

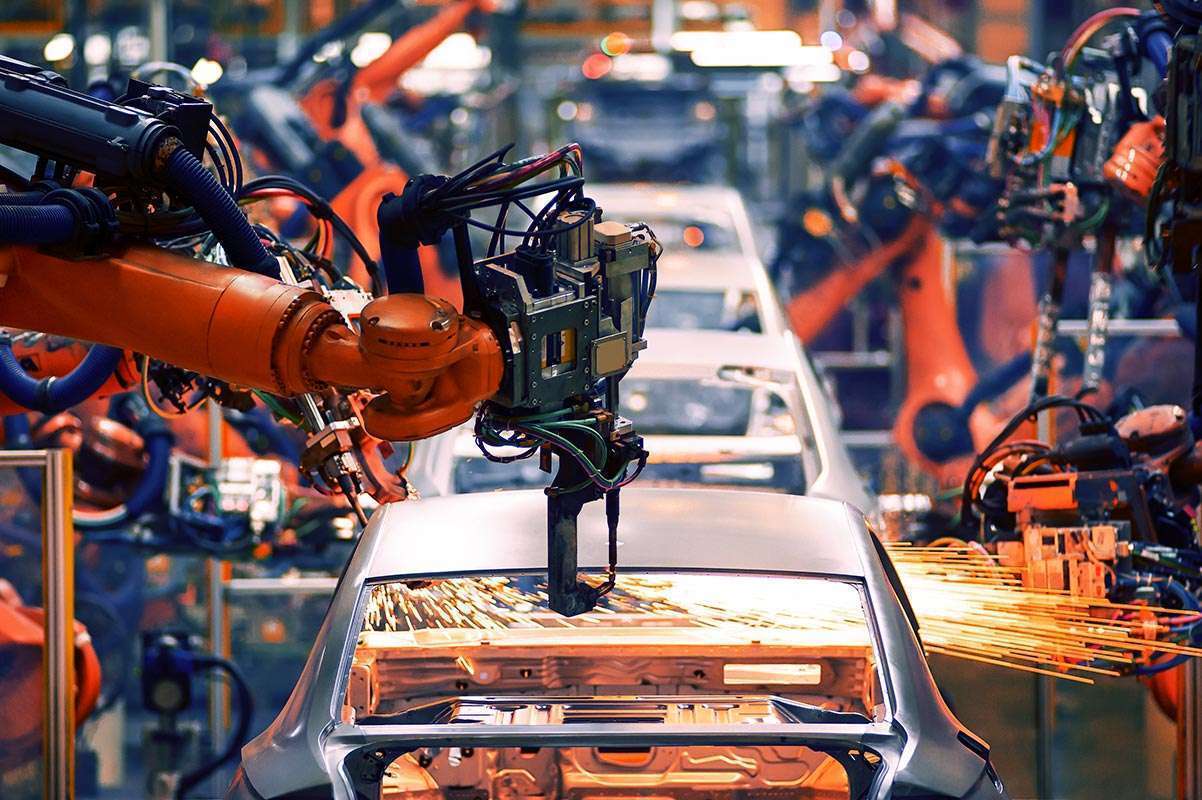

Seit mehr als 30 Jahren fokussieren wir uns als Beratungsunternehmen auf die Lösung komplexer Managementherausforderungen in Unternehmen der produzierenden Industrie. Im Mittelpunkt unserer Tätigkeiten stehen Wertschöpfungsprozesse und die Wertsteigerung für unsere Kunden. Wir arbeiten ergebnisorientiert und schaffen nachhaltige Wettbewerbsvorteile für unsere Kunden.

Beratung Branchenspezifisch

Unsere Branchen

Facts & Figures

Zufriedene Kunden

Projekte

Jahre Firmenzugehörigkeit

Jahre Erfahrung

Hidden Champions Awards

Wir wollen Dich

Arbeiten bei TMG

Wenn Du eine Karriere anstrebst, die so unverwechselbar ist wie Du selbst, dann bist Du bei uns richtig. Bei uns gibt es kein Up-or-out-Prinzip. Wir bieten Dir eine Vielzahl anspruchsvoller Aufgaben und Entwicklungsperspektiven in einem Arbeitsumfeld, das von hoher Leistungsorientierung, großer Kollegialität, jeder Menge Gestaltungsfreiraum und einer ausgesprochen familienfreundlichen Work-Life-Balance geprägt ist.

Auf dem laufendem

- Trends

- News

- Blog

SCHLÜSSEL ZUR NACHHALTIGKEIT

CIRCULAR ECONOMY

Die Antwort der produzierenden Industrie auf Nachhaltigkeit ist die Kreislaufwirtschaft entlang der eigenen Wertschöpfung. Die Erfahrungen von TMG Consultants bestätigen, dass der schnellste und effektivste Weg zu einer nachhaltigeren und dennoch wirtschaftlichen Unternehmung auf dem Fundament der Circular Economy aufsetzt.

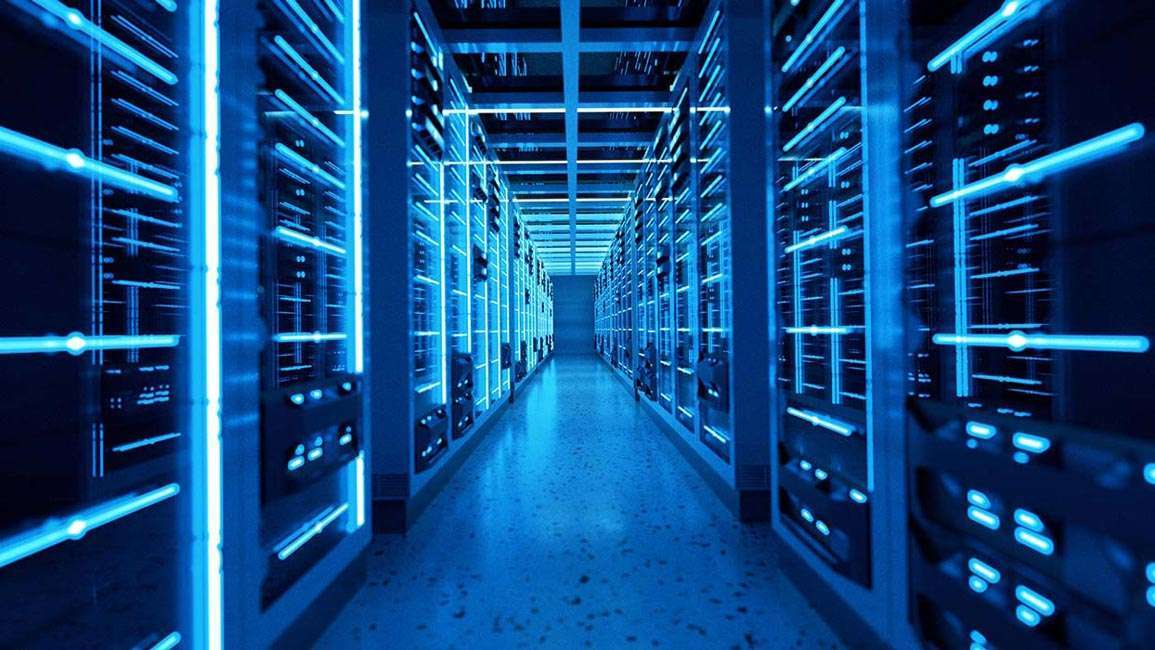

Digitalisierung

Umstellung auf S/4HANA

Es entsteht Handlungsdruck: 2027 läuft die Wartung des SAP R/3 Systems offiziell aus – SAP S/4HANA kommt! Für mittelständische Unternehmen bedeutet dies, dass sie sich mit einem Projekt in der Königsklasse der Komplexität und den damit verbundenen Risiken intensiv auseinandersetzen müssen. Die Angst vor dem Scheitern ist im deutschen Mittelstand groß und berechtigt. Regelmäßig überschätzen sich selbst große und erfahrene Unternehmen bei der Umsetzung solcher Projekte.

Ihr Unternehmen noch effizienter

EFFIZIENZSTEIGERUNG UND KOSTENSENKUNG

Alle aktuellen Wirtschaftsprognosen und ökonomischen Vorzeichen weisen in Richtung einer konjunkturellen Abschwächung. Die Brexit-Diskussion sowie die Zoll- und Außenhandelsstreitigkeiten zwischen den USA und China bzw. der EU tragen ferner dazu bei, dass die produzierende Industrie mit einem hohen Maß an Unsicherheit und unbeantworteten Fragen in die nächsten Quartale blickt.

News

INSIGHTS 31 erschienen: „Kurzzyklische Industrialisierung“

Egal ob Lieder oder Filme, Bücher oder Autos:Klassiker sind etwas ganz Besonderes. Manchmal verschwinden sie für ein...

TMG Studie: So steht es in Deutschland um Business Process Management (BPM)

Was lange währt, muss nicht unbedingt gut werden. Aber was lange relevant ist, sollte unbedingt im Blick behalten...

Hidden Champion 2024/2025

Zum fünften Mal in Folge hat sich die TMG Consultants GmbH als führende Top-Managementberatung für die produzierende...

Blog

Indische Dabbawalas – was wir von ihnen für eine moderne Arbeitswelt lernen können

Die Dabbawalas von Mumbai, Indien, sind bekannt für ihre bemerkenswerte Effizienz bei der Lieferung von Mittagessen an...

Wieso ich eigentlich nie in die Beratung wollte…

... und jetzt doch dort bin. Zu Studentenzeiten war ich in einer studentischen Unternehmensberatung aktiv. Die Zeit...

Die Zukunft des Kundensupports

Menschliche Interaktion vs. KI-basierte Assistenz bei 7Q1Seit meinem ersten Tag bei 7Q1 bin ich im Bereich...